Oyster shell and rice husk can be turned into low-cost building materials with antimicrobial properties

26 Apr 2024

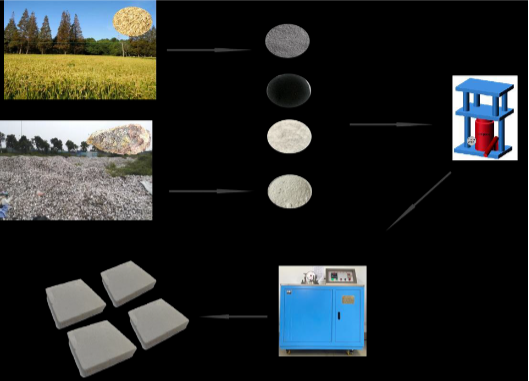

The development of green and low-cost functional building materials is increasingly becoming one of the primary goals in the construction industry, triggering interest in the use of biomass waste as substitutes for traditional construction materials. This work makes use of biomass waste, particularly oyster shell as the calcium material and rice husk as the silicate material, to produce calcium silicate boards. These boards were incorporated with an antimicrobial composite material (CuSe/CaCO 3 ) to endow the boards with an antimicrobial functionality that can effectively inhibit the growth of pathogenic microorganisms, such as bacteria (E. coli and S. aureus) and fungi (C. albicans). The utilization of biomass waste in creating functional building materials can help in mitigating environmental pollution and in reducing the overall cost of construction.

The antimicrobial effect can be attributed to the presence of CuSe nanoparticles, which are capable of effectively inhibiting microbial growth through a combination of (i) light-induced generation of radicals, (ii) release of copper ions, and (iii) photothermal heating. The experimental parameters (e.g. Ca/Si ratio, molding pressure, curing time and temperature, and CuSe/CaCO 3 loading amount) were varied to determine the optimal parameters for fabricating calcium silicate boards with the most satisfying flexural strength and antimicrobial efficacy. Our study aims to pave the way for the green fabrication of functional calcium silicate boards through valorization of biomass waste.

Authors: Xiaoyan Zhao, Yugi Zhai and Yongcheng Zhou (School of Civil and Transportation Engineering, Hebei University of Technology), Zhihua Liu, Zewen Kang and Bingging Wang (College of Chemical Engineering and Materials Science, Quanzhou Normal University), Michelle D. Regulacio (Institute of Chemistry, University of the Philippines Diliman) and Da-Peng Yang (School of Rehabilitation Science and Engineering, University of Health and Rehabilitation Sciences and College of Chemical Engineering and Materials Science, Quanzhou Normal University)

Read the full paper: https://doi.org/10.1016/j.conbuildmat.2023.134505